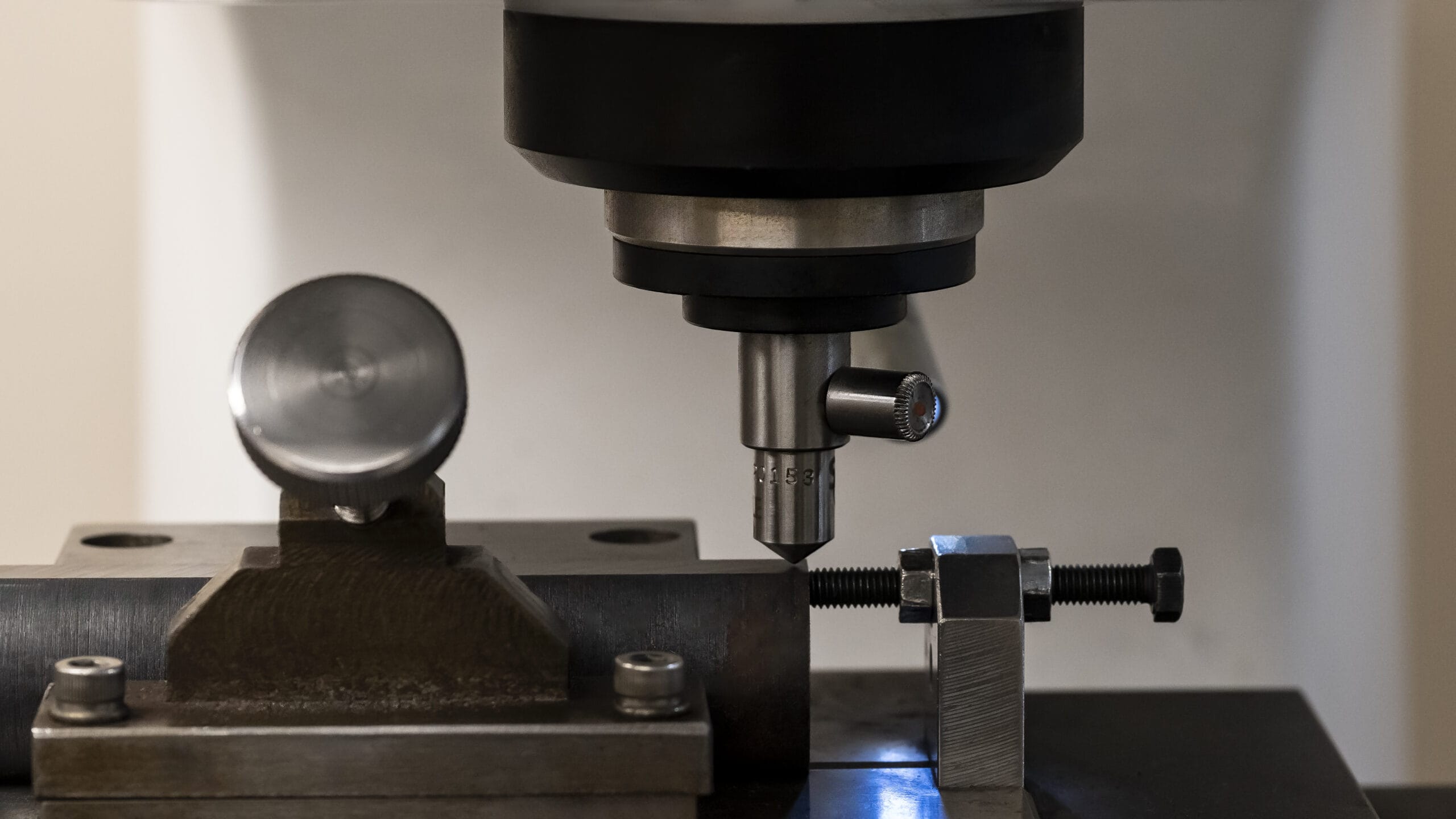

Having researched, bought and trained to work with the various technically sound equipments for carrying out quality tests, we have managed to assure delivery of top-end products to the clients. Some of the machines at our plant that carry out quality checks are:

4140 / EN19 / 42CrMo4 Bars – Test Process Chart

| Test Name | Purpose | Standard/Method | Stage |

|---|---|---|---|

| Chemical Composition Analysis | Verifies material grade and alloy content | ASTM E415 / Optical Emission | Raw Material |

| Ultrasonic Testing (UT) | Detects internal flaws or voids | ASTM A388 | After Forging/Rolling |

| Hardness Testing | Measures surface hardness | ASTM E18 (Rockwell) / Brinell | Final Product |

| Tensile Test | Determines tensile strength, yield, and elongation | ASTM A370 | After Heat Treatment |

| Impact Test (Charpy V-Notch) | Measures toughness at room or sub-zero temperatures | ASTM E23 | On Request / Critical Apps |

| Microstructure Examination | Evaluates grain structure, inclusion, and phase distribution | ASTM E112 | After Heat Treatment |

| Magnetic Particle Inspection (MPI) | Detects surface and near-surface cracks in ferromagnetic materials | ASTM E709 | Post Machining |

| Dimensional Inspection | Verifies size, tolerance, and straightness | As per client specs | Final QC |

| Surface Finish Inspection | Checks for scale, rust, cracks, and finish quality | Visual / Manual | Final QC |

| Heat Treatment Report | Confirms process parameters: temperature, duration, cooling medium | Internal Record / Cert | Post HT |

| Third-Party Inspection (Optional) | Ensures compliance by external certifying agencies like BV, SGS, TUV, etc. | Client-Specified | Final Dispatch |

.jpg)

.png)

.jpg)